Turntables

They change the direction of movement of the load. Goods from transport lines are merged and divided.

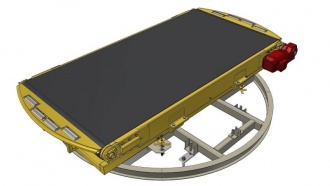

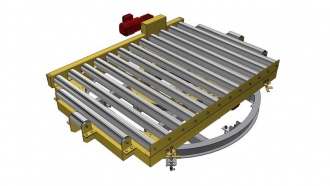

Turntables are often part of conveyor systems used by manufacturing companies and distribution centers. It is used to change the direction of movement of the load and can be fitted with rollers, chains and belts. It turns and moves products heavy up to several tons.

It changes the direction of transport by up to 360°

Belt, roller and chain conveyors often complement turntables. They adjust the path of the goods by up to 360 °, making it easier to work with different types of load. They simplify the construction of the transport route and save space in halls and warehouses. Turntables most often move pallets - steel, plastic or wooden - but they can also move piece products in the horizontal direction.

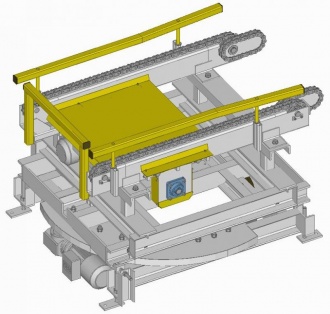

Splits pallets or merges them from different directions into one

Turntables can not only rotate the goods by any angle, but also divide it and send it to several different routes. This makes pallet sorting more convenient and faster. Turntables coming from several different lines into one are just as easy to combine turntables.

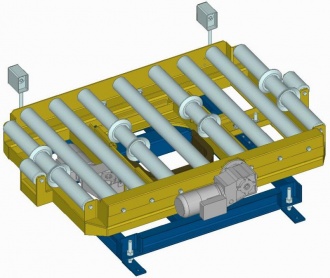

The turntable includes a belt, roller or chain conveyor

Turntables usually consist of a top and a bottom. The upper part consists of a conveyor - belt, roller or chain. In the lower part there is a turntable frame and the rotating mechanism itself. It can be either electromechanical or pneumatic. The cable stacker ensures the supply of electrical installations in lines where the load rotates 90°. The ring collector then performs the same function in places where the goods rotate 360°.