Inter-floor transport of metal pallets: empty and full pallets are moved fully automatically

written: 10.04.2025

Pallets in motion – effortlessly and without unnecessary delays

In the automotive industry, every detail counts – just as it does in material handling. That's why, when we designed a transport system for a company that manufactures automotive body parts, we focused primarily on smooth operation, efficiency, and safety.

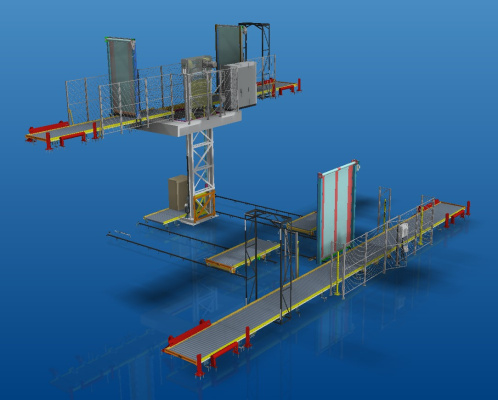

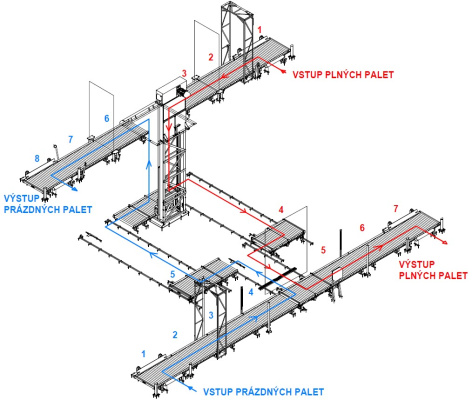

The conveyor system for inter-floor transport of metal pallets and pallets with products is a comprehensive automated solution that enables flexible material handling within the production plant. It reliably and quickly moves empty and full pallets between floors, thus optimizing overall logistics in production.

Power, precision, reliability: the robust conveyor system can transport even unusually large and heavy pallets

The system is based on roller conveyors, which are used for horizontal movement of pallets between the input and output workstations. Their design allows for easy transport of heavy pallets with a load capacity of up to 2,500 kg and a maximum height of 2,950 mm. The roller conveyors also have fixed stops, ensuring the precise positioning of pallets during handling.

Advantages of the new system:

- Fully automated operation – the new solution has increased the efficiency and productivity of pallet transport.

- Greater work safety – the risk of injury is minimal thanks to protective elements and control systems.

- Flexible transport – the system moves pallets of various contents, both empty and full.

- Space saving – thanks to the vertical conveyor and clever layout of the available zones, the production hall is used to its full potential.

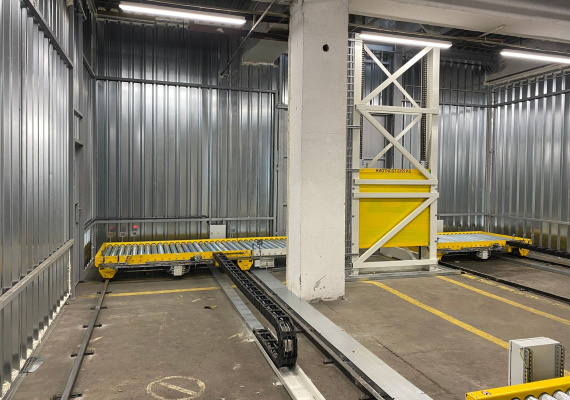

Vertical conveyors and transfer carts ensure smooth movement between floors

Pallets are transported between the ground floor and the lower floor by a vertical conveyor that connects the two separate sections of the system. The section for empty pallets serves as a storage area with a capacity of 8 positions, and empty pallets are transported from the bottom to the top. The section for full pallets allows for the storage of 7 positions, and pallets are transported from the top to the bottom.

To ensure the smoothest possible transfer between floors and zones, both sections are also connected by transfer trolleys with roller conveyors. Pallets are loaded and unloaded by forklifts, which allow them to change direction and move horizontally between different zones. This makes pallet transport work perfectly even in places where fixed conveyors cannot be used.

Inter-floor pallet transport also uses weighing conveyors

During transport, the height, width, and weight of the pallets are checked. The system only allows pallets that meet the specified parameters to pass through, thus reliably preventing collisions and possible damage. In addition, the entire solution has protective fencing that prevents people from entering dangerous areas, and all entrances and exits from the line are secured by light barriers. There are high-speed doors on the ground floor to prevent access to the vertical transport area, and protective fencing in the basement. The system doors also have opening sensors for automatic detection of unauthorized access.

Are you interested in our solution for transporting metal pallets between floors? We would be happy to design a suitable conveyor system for your company. Just contact us.