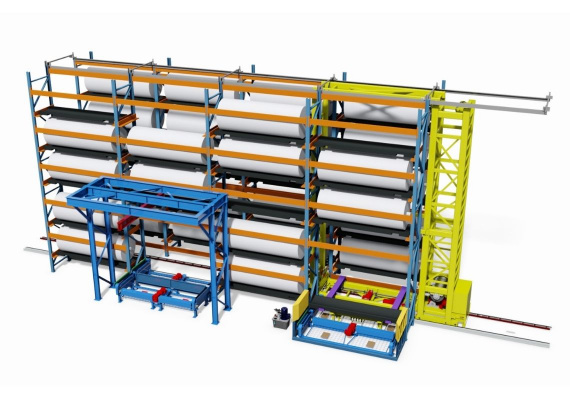

Automatic roll storage increased hall capacity by 70 percent

written: 07.01.2021

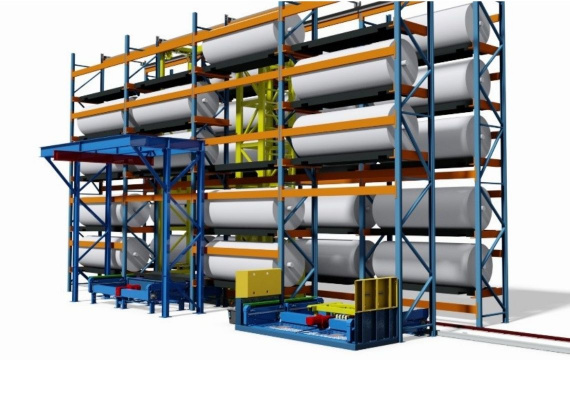

Automated racks for 180 tons had to be perfectly accessible

A manufacturer of fabrics for airbags and coffin linings was looking for the best way to store product rolls between operations. They needed to place the rolls in the hall in a way that took up as little space as possible, while still allowing for easy handling at every stage of production. Originally, the rolls were lying on an open area, next to each other, so they were not always easily accessible for the operator. We found a better solution and placed the product rolls at a height.

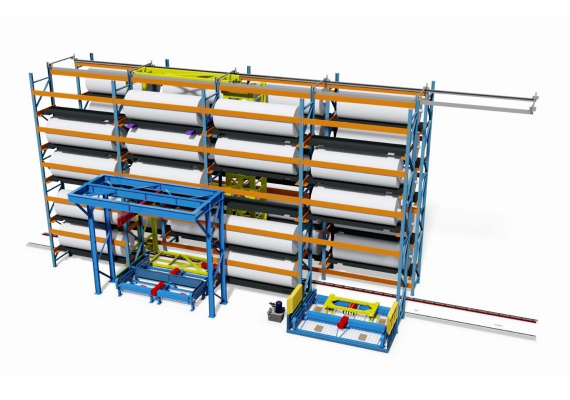

New warehouse racks reach up to 7.2 meters in height

The automatic warehouse works with rolls of various sizes

Each of the 106 positions has its own steel pallet in the shape of a tub. It is not designed for only one type of product, but can accommodate rolls of various dimensions, lengths and widths of the winding, without the need for their prior identification. We have also added stops to the automated racks to prevent the handling unit from falling out, modified the loading trolley and secured the warehouse against damage by the rocker.

New storage technology protects textiles from contamination

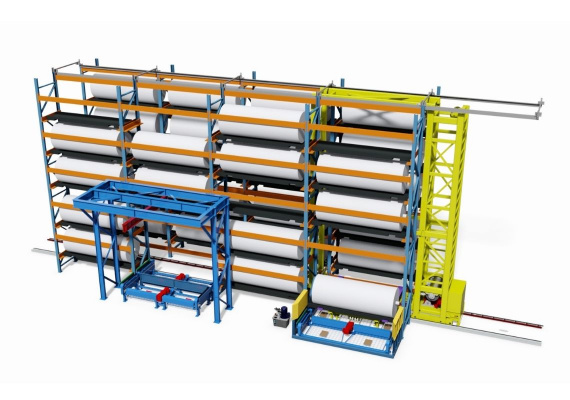

The transport tray protects the textiles from dirt and mechanical damage. There is no direct contact between the roll and the unloading device. We have left an aisle between the storage racks for the automatic stacker with a rope lift. The racks, including the stacker, do not exceed a width of 3.2 meters. The two omitted lower floors of the automated racks then allow for easy storage and unloading of the rolls.

The automatic warehouse stores in service or automatic mode

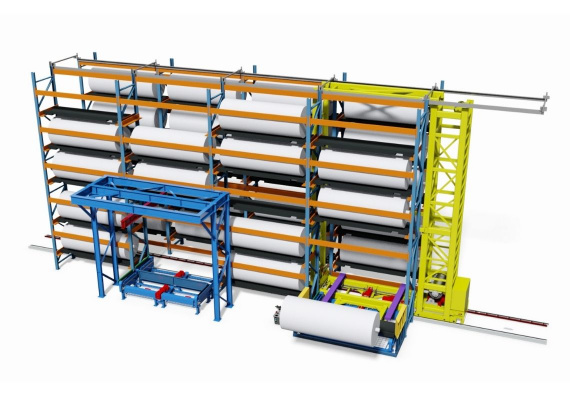

In service mode, the operator controls all movements of the device using buttons and switches. In automatic mode, the warehouse operates according to programmed logic and operator requirements. The input and output are always formed by pairs of chain conveyors - internal to the stacker and external, which the operator uses to store or retrieve rolls. The chain conveyors divide the sectional doors. Thanks to this, the operator can perform all work safely and without limiting the work of the stacker.

What exactly does the storage process look like? The operator first brings the roll of goods to the storage position and calls for an empty pallet by pressing a button. The stacker brings the closest one and places it on the internal chain conveyor. The safety sectional door then opens and the pallet moves to the external chain conveyor. The operator places the roll on the pallet, scans it with a barcode reader and presses the storage button. The full pallet then moves back to the internal chain conveyor and the rack stacker places it in the desired location.

A hoist helps warehouse technology with stock removal

When picking, the operator brings the mobile roll rack (type A trolley) to the exit within reach of the hoist. On the touch screen, he selects which roll he wants to pick up. The stacker then brings the roll on a pallet and places it on the internal chain conveyor. After placing it, the sectional door is raised and the roll is transported to the external chain conveyor under the hoist. The operator then uses the hoist to load the roll into the mobile rack and gives the instruction to return the empty pallet to the warehouse.

Would you need a similar automated warehouse? Do not hesitate to contact us. We will prepare a tailor-made proposal that takes into account the specifics of your operation.