We hid the scale conveyor under the floor

written: 27.02.2022

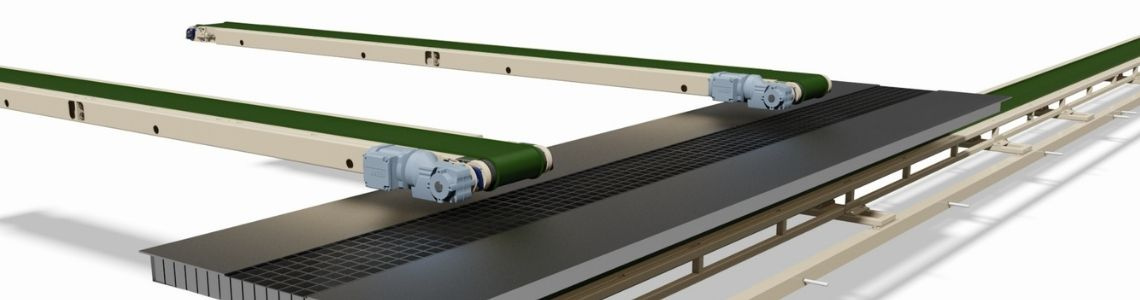

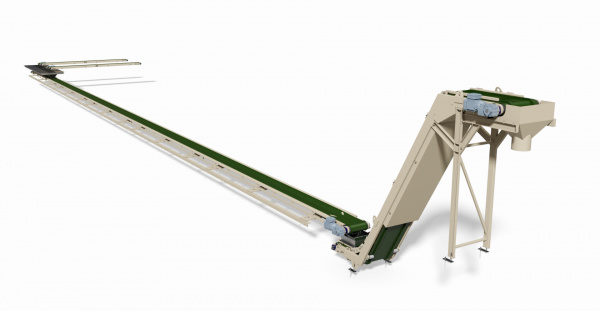

A 28-meter-long conveyor with a capacity of 500 kg/day had to be placed underground

A manufacturer of dispersed reinforcement for concrete, operating worldwide, needed to design a conveyor system for a new production hall. The central removal of slag from slag removers needed to be placed in a corridor measuring 800 × 800 mm below floor level. The conveyor was to pass under the floor into another room, where the slag is transported approximately 2 meters above floor level. How did we tackle the task?

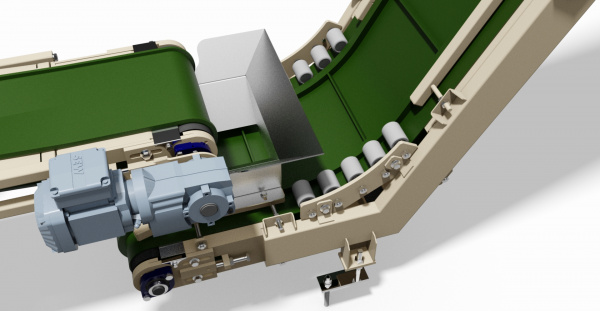

Excellent. We have been working with the company since 2010 and have supplied them with more than 70 devices during that time. We therefore knew what the customer's needs were and how best to meet them. What's more, they already use a similar system in their company. However, we supplied a new design that is twice as powerful as the existing solution in another hall. The conveyor is also twice as long, so it can serve more devices. In addition, the motors meet the stricter ICE3 efficiency standards, so we expect the customer to save considerable energy costs.

The slag conveyor does not interfere with anyone, yet allows for easy installation, maintenance, repairs, and cleaning

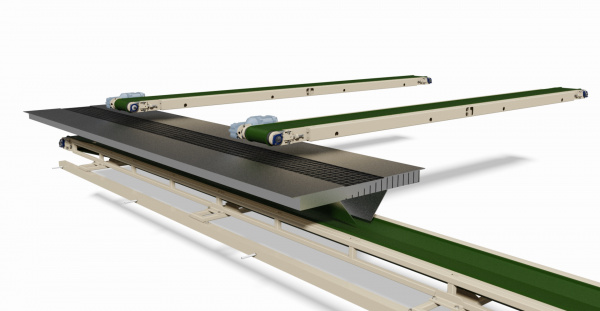

We placed the new central conveyor in the corridor below floor level and covered it with a grate with a hopper. If we had placed it on the floor in the traditional way, it would have taken up too much space. In addition, the machines are located on both sides of it, so it would have made maintenance and servicing difficult. The conveyor does not get in anyone's way underground, and because it can be completely dismantled, it is easy to clean. For service inspections, which take place approximately twice a year, it is sufficient to assign two people who can completely dismantle the entire conveyor within four hours.

We thought about the future and prepared the conveyors for the possible connection of additional lines

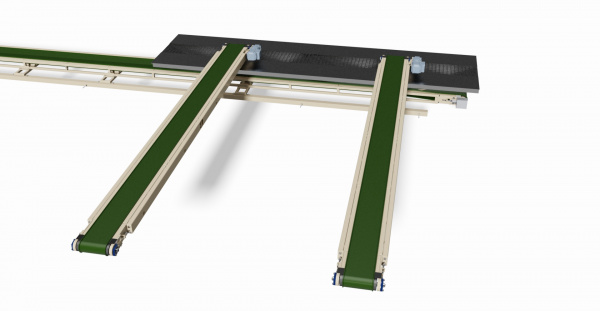

The customer needed to design conveyors for decanters so that they could be connected to a central conveyor with a transfer to a discharge conveyor, where a BigBag would be placed. We prepared the conveyors for easy installation and integration into the decanter. We placed one half of the conveyor inside the deburring machine and bolted the other half to the machine from the outside.

The entire solution includes five belt conveyors with side guards on the belt to prevent unwanted spillage, a central belt conveyor with a V-shaped belt and side guards, and a Z-shaped belt conveyor with cross guards and a side bellows with a hopper that is ready for BigBag attachment.

Are you interested in a conveyor system for dross? We are sure to find a suitable solution for your company. Just contact us.