We have accelerated the transport of pallets with loads up to 3 metres high

written: 21.09.2022The new system ensured faster transport of pallets weighing up to 1.5 tonnes

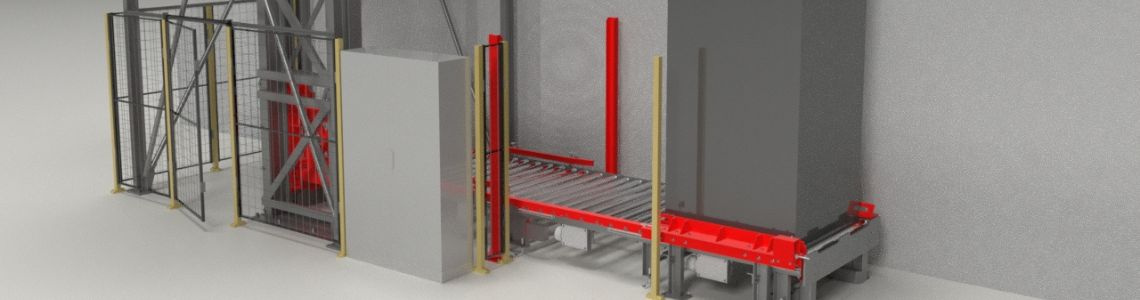

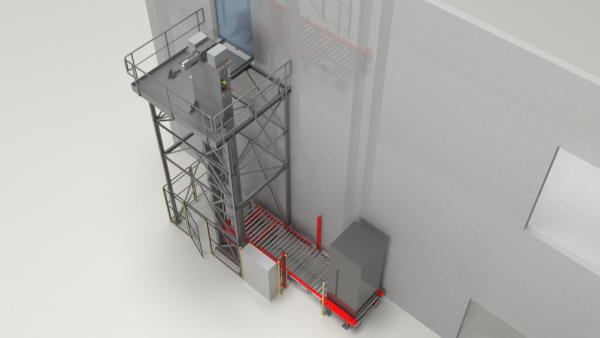

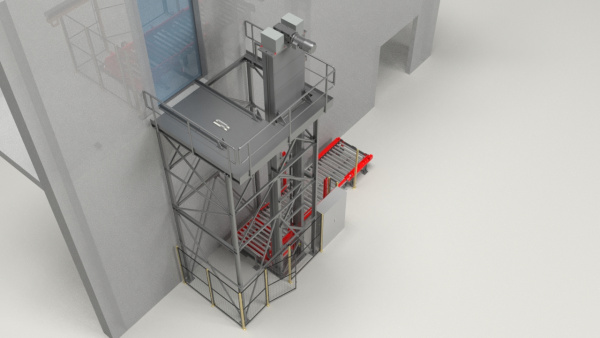

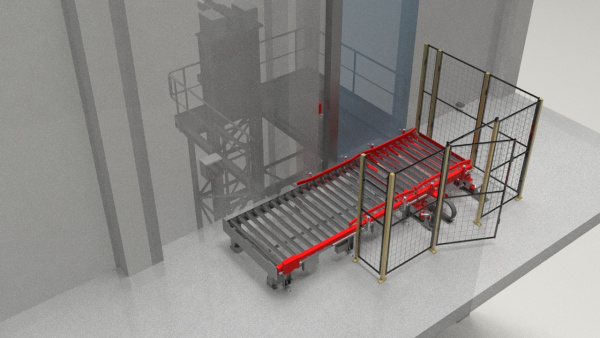

We have extensive experience with pallet conveyors. We often create systems that penetrate several floors and walls. A transport and handling company from Frýdek-Místek was also interested in the innovation of inter-storey pallet transport. We created a solution for them that can handle heavy and high loads. We prepared our own design of the steel structure of the platform and used both horizontal and vertical conveyors.

Sophisticated warehouse logistics handles even atypical pallets

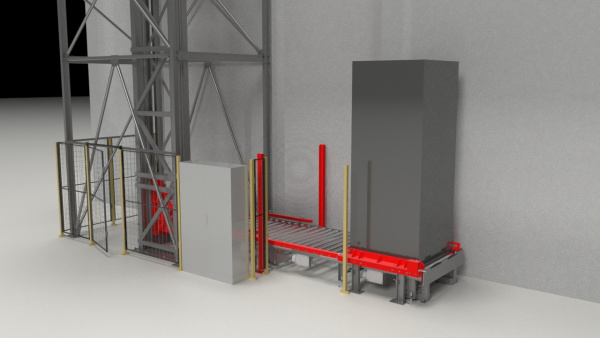

The new conveyor system is used for the reversible transport of pallets. The load is moved between the entry and exit points and travels from the ground floor to the first floor and back. The entire system consists of roller conveyors, a vertical conveyor, a transfer trolley and a sliding fire cap. And what does bi-directional pallet transport look like in practice?

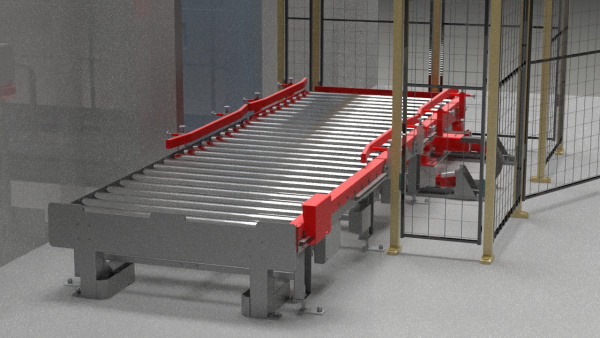

First, the pallet is placed on the infeed conveyor with the help of a forklift and the operator confirms the loading of the pallet with a button. The pallet is then transferred from the infeed conveyors to the hoist, which takes the pallet to the 2nd floor. The sliding fire cap is moved away and the pallet is passed onto the transfer trolley and then onto the exit conveyors. The operator removes the pallet from the conveyor and confirms its removal with a button.

The conveyors move both wooden EUR pallets with dimensions of 1200 × 800 mm and atypical pallets with dimensions of 1200 × 1200 mm and weights up to 1500 kg. They can also handle high handling units without any problems. Full pallets can be up to 3000 mm in height.

Professional technical security protects operators and cargo

The new warehouse logistics places great emphasis on security. The conveyor system has an automatic fire lock and a backup power supply that powers the conveyors in the event of a power failure. The entire system has security fencing with lockable entrance gates and safety netting on the tube, including a safety platform. There is also muting that detects a pallet flowing on the conveyor and distinguishes it from a passing person.

Transport performance:

- Transport/handling speed: max. 30-45 pallets/hour with the possibility of future expansion to 90 pallets/hour.

- Conveyor speed: approx. 15 m/min.

- Transfer carriage speed: approx. 15 m/min.

- Vertical conveyor speed: approx. 25 m/min.

- Working hours: 3-shift operation, 7 days.

The challenges of the future were also considered in the automation of pallet transport

The advantage of the modular pallet transport system is that it can be easily expanded with additional conveyor sections if required. You can also add outfeed conveyors in the opposite direction, add downstream rack stackers or other automatic storage systems.

Are you also interested in modernising or automating pallet transport? Contact us. We will be happy to prepare a tailor-made offer including a price calculation.