Transfer trolleys in the foundry run at millimeters precisely

written: 14.09.2020The foundry project brought design challenges

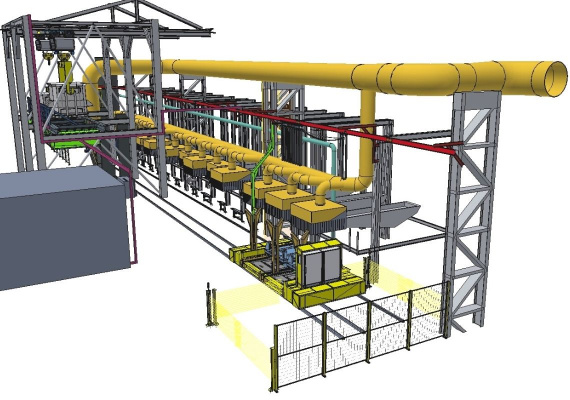

The new solution had to overcome several challenges - overcoming the large height difference between input and output, perfectly matching the movements of the device, keeping the time for mating or precisely positioning in two sampling positions. We had to secure the hoists of the hoist against rotation and compensate for the swing and rotation of the collection container during vertical transport. At the same time, the contract also included the modification of the old car to a new steering and electrical supply. How did we handle all this? We've delivered a solution that satisfies this, and added a few new features for more powerful operation.How does the mating work? The new system with transfer trolleys works completely automatically

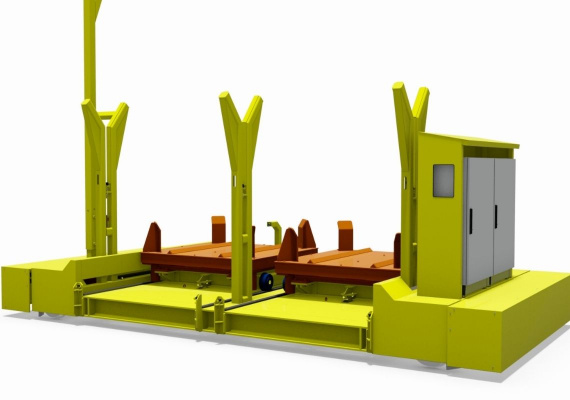

Our device works in fully automatic mode. When sorting a metal charge, ie weighing the individual components according to the recipe entered in the control system, the transfer sorting car travels along the track under 12 hoppers and sorts the metal material from the hopper feeders. After filling the batch, it will slide under one of the hoists - the accuracy of its stopping is in the order of millimeters.After moving the car to the pick-up position, the hoist removes the collection container with the charge from it, lifts it to a height of 5 meters, moves it 7 meters horizontally above the loading wagon and dumps it there. As the charge travels to one of the foundry's 6-ton melting furnaces, the hoist transports the emptied collection container to the sorting truck, followed by a new sorting.

What exactly does the solution in the foundry consist of?

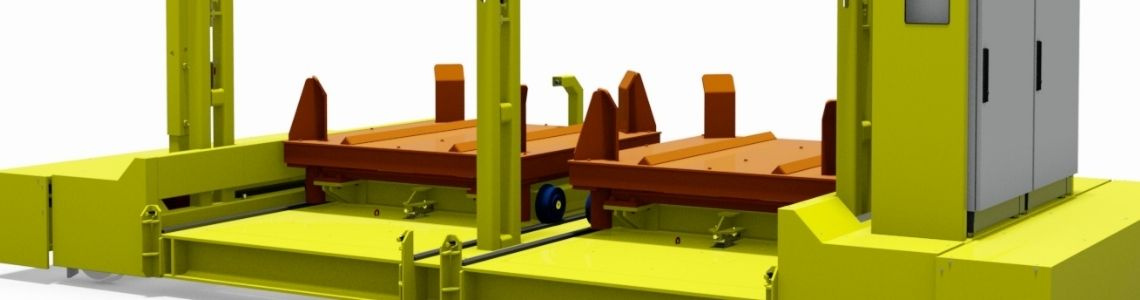

- sorting car with a length of 6.2 m and a load capacity of 10 tons

- 3 collection containers with a capacity of 3.8 tons

- 2 load-bearing beams with a load capacity of 5.5 tons

- 2 hoists with a load capacity of 8 tons

We've made it easier to control and added a manual matching feature

The new sorting car is safer and easier to handle. It enables manual sorting with the display of the weighed state directly on the car and its power supply is provided by an overhead track at a height of 7 meters. In addition, it is part of a unit that has contributed to a significant reduction in the dustiness of the operation and fugitive emissions (volatile substances that cannot be discharged through the chimney or vent, but escape freely into the working environment).Thanks to the transfer trolleys, the mobile crane can comfortably pass through the hall

Our transfer trucks have eliminated the problem of the passage of the truck crane. With conventional trucks, the sorting wagon would have to move to the farthest position and wait there for the passage of the truck crane so that the free loops of cables do not impede the passage. However, our transfer trolleys work on the opposite principle. The lock, by which they are connected to each other, protects the cables from stress, and when the cable loop is tensioned, the carriages are gradually unlocked from the last to the first pulling one. Thanks to this, the mobile crane can pass through the hall without any problems even during the operation of the sorting car.The installation took place during operation only with extraordinary outages

Every hour is expensive in the foundry. That is why we installed the new equipment in operation mainly on weekends and only with extraordinary outages. We then wanted to save time for the employees themselves. We have reduced the handling time required for weighing materials to 13 minutes. We programmatically optimized the sorting machine so that in the event of a sudden stop during melting, the operator can manually return the sorting to the position before stopping and the machine will complete the melting.Are you interested in our solution? Do not hesitate to contact us. We will be happy to prepare a tailor-made offer for you.