The conveyor bridge released the hands of 12 workers

written: 10.04.2020

The tile manufacturer needed to create a conveyor bridge connecting the production with the distribution center

We first looked at a company producing custom tiles in 2008. At that time, we designed a new pallet transport system for one of the domestic branches. In 2018, the client turned to us again with confidence when he needed to innovate the transport of pallets from production to the warehouse in another branch. The current solution was very inefficient and expensive. It consisted of the use of tractors with loaded trailers, which moved pallets 7 days a week, in 3 shifts.

The 250-meter-long conveyor accelerated pallet transport and changed the workload of 12 employees

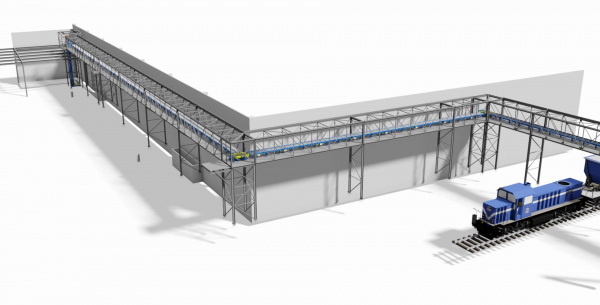

We created a tailor-made solution for the company, which fully replaced the work of tractors. The tiles are now being moved from production to the warehouse via a steel corridor at a speed of up to 60 europallets weighing 1.3 tonnes per hour. The total length of the transport route is approximately 250 meters and has an elevation gain of 8 meters. When designing it, we had to think carefully about the installation of the conveyor bridge - where its foundations will be, how we will connect it to the new production hall towards the warehouse and where the whole route will lead to be conveniently located above the existing train siding and well connected to utilities.

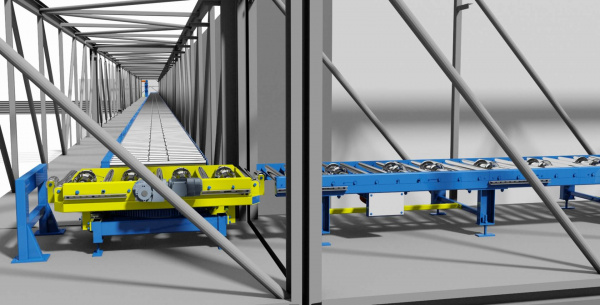

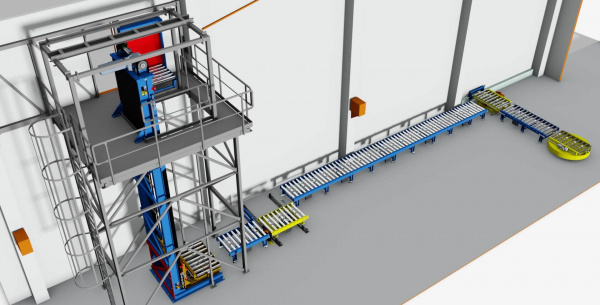

A bent above-ground corridor with special pilots proved to be the ideal solution. At the beginning and at the end of the conveyor bridge there are lifts with roller conveyors, in the middle there are straight roller conveyors and turntables with roller conveyors.

The entire pallet transport solution thus consists of the following devices:

- roller conveyors straight

- roller conveyors on turntables

- shifters with roller conveyor

- vertical conveyors with roller conveyors

We also unified spare parts for both branches of the client. Thanks to the new solution, 12 employees who previously worked in the transport and operation of tractors with trailers have their hands free. They can thus engage in more beneficial activities.

Are you interested in a similar solution? Contact us and we will prepare a tailor-made offer for you free of charge.