The automatic conveyor line improved the production process of cooling electric batteries

written: 26.08.2020

The manufacturer needed a powerful automatic line that would integrate a soldering furnace at a height of 3.5 meters

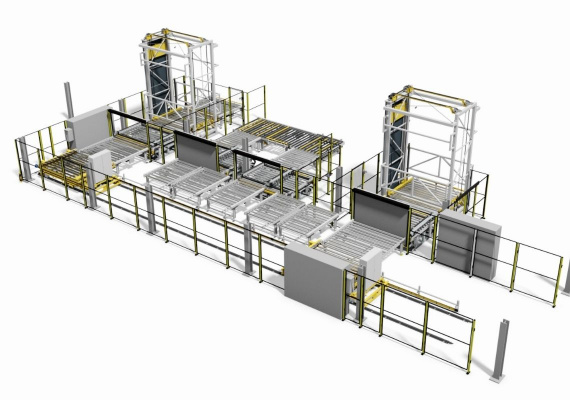

A cramped hall, several speeds of movement and the need to keep precise spacings. The new conveyor system had to deal with all this. The company needed to build a powerful line transporting the cooling of electric batteries for BMW and VW cars. Today, the new conveyor system transports two types of frames with car parts on an 78-meter-long automatic line.

Our solution handled different speeds and saved space in the hall

We have created a conveyor line that works automatically, completely unattended and can be controlled remotely. Thanks to the practical stacking of transport frames, we have also significantly saved storage space.

The frames with car parts are stacked on top of each other and disassembled again using a palletizer. There is a movable stopper on all of them to compare the handling unit. We used the free space below the level of the furnace as an accumulation warehouse, and in order to make the best use of the given space, we introduced transport in 10-piece stacks. Thanks to this, our client can place even more technologies in the hall.

The newly developed palletizer also completed the tailor-made conveyor line

The input and output of the conveyor system consist of four robotic workplaces. Specifically, the whole line consists of the following parts:

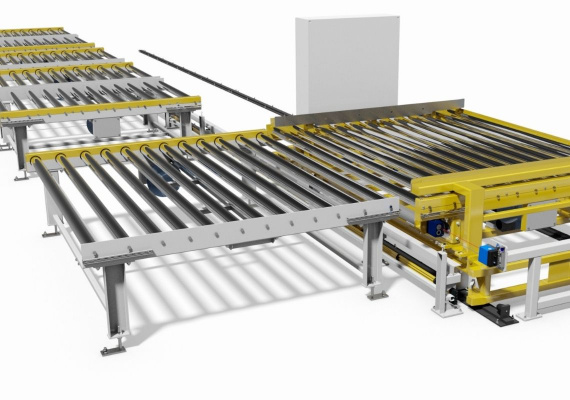

- roller conveyors

- chain conveyors

- chain-roller transitions

- vertical conveyor

- transfer trolley with roller conveyor

- and a newly developed palletizer for stacking 10 frames with adjustable conveyor widths.

The automatic line consists mainly of roller conveyors. In places where the metal frames with coolers turn, there are nested chain conveyors and vertical conveyors carry the load to the elevated furnace. Frames with car parts changing direction are regulated by a movable stopper or a fixed stop for comparing goods. Employees also use transfer trolleys in the warehouse area. There are four on one track, which are interchangeable.

The new automatic line is also ready for future challenges

The conveyor system is maximally secured. It can react to a possible furnace failure or power failure. The transport between the floors and the longitudinal transport in the warehouse are doubled in order to ensure the smooth running of production. In addition, the entire solution not only meets the current needs of the company, but also thinks about its future development. The conveyor system is structurally and capacitively prepared for the addition of the second furnace in the following years and expansion with other technologies.

Are you interested in our solution? Do not hesitate to contact us. We will be happy to prepare a tailor-made offer for you.