Robot-assisted automation of production processes has eliminated laborious manual work

written: 09.01.2022

Automation of production processes has put an end to laborious manual depalletizing

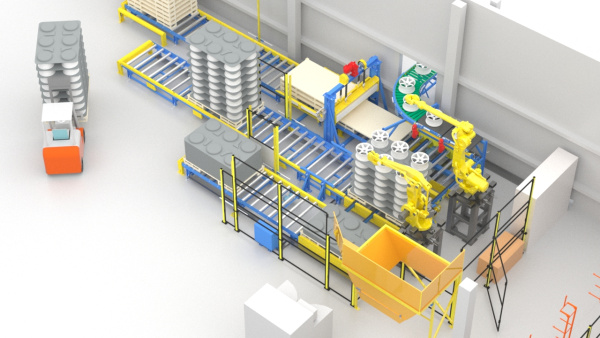

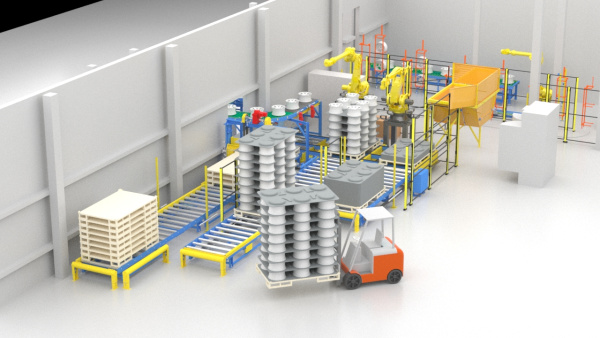

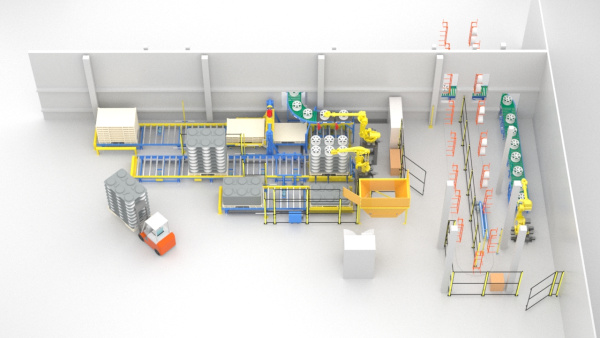

Our customer wanted to automate the transfer of aluminum wheels. These were moved from metal pallets in the inter-operational storage area to an overhead conveyor, which then transported them to the paint shop. The condition was minimal interference with the existing overhead conveyor and the preservation of the possibility of manual hanging in case of servicing the equipment.

The new system has completely replaced monotonous and exhausting manual labor, which required workers to lift aluminum wheels weighing up to 22 kg. The new line can now process up to 500 wheels with diameters of 16–22" per hour. The wheels are delivered on three pallets of different sizes.

It was completed in a month and a half. The transition to robotic process automation took place with minimal disruption to production

Before automation, the operator loaded a full pallet of wheels with spacers into the overhead conveyor area. Then, by gradually hanging the wheels on the overhead conveyor, the operator dismantled the pallet. Now, the operator uses forklifts to place a full pallet on the input roller conveyor and, at the end, a pair of robots performs depalletizing. The operators remove empty stacked pallets and pallets with stacked spacers from the adjacent output conveyors.

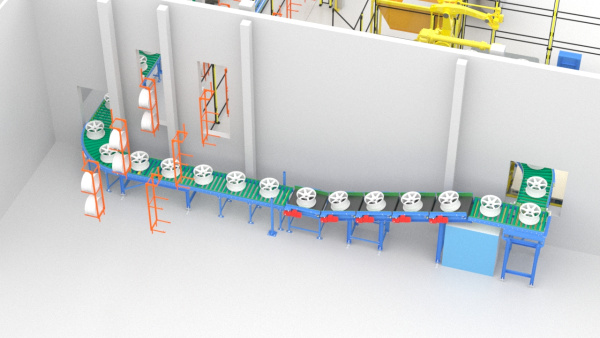

Depalletizing is performed by a pair of robots, one of which removes the spacers forming the Mirelon and plastic pad, while the other transfers the wheels to the accumulation conveyors leading to the hanging station. During transport, the wheels are checked and, in case of non-compliance, removed from the line. At the suspension point, the pair of wheels is centered and a third robot suspends it on the suspension track using a conveyor-tracking system (by adjusting the path of movement). Everything runs in a fully automated mode.

We took care of the delivery and assembly of the mechanical parts (we supplied roller and chain conveyors for pallets, a stacker for empty pallets, a centering device, belt and roller conveyors for wheels, including design work). The integration of the automated workstation took six weeks, with minimal disruption to production.

Are you interested in learning more? Or would you also like to automate your production processes? Contact us. We will be happy to prepare a customized proposal for you.