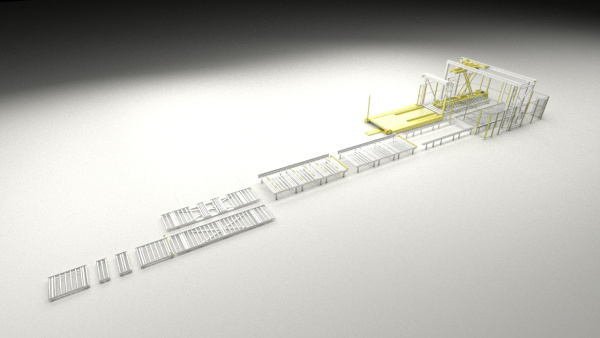

Our production line lined up the pallets. We've sped up production and stacking

written: 13.05.2021

We delivered the pallet production line within 3 months

A company specializing in custom packaging and logistics needed us to design a line for the production of wooden pallets. The new solution had to meet several criteria:

- The new line had to work with a large portfolio of pallets of different sizes.

- The material flow had to change direction twice in the production hall.

- A non-standard sized roller had to be prepared.

- The line had to enable precise alignment and stacking of pallets.

- The company needed to deliver a solution within 3 months.

- And we had to ensure its assembly in Hungary.

We met all the client's needs and even accelerated the production of pallets

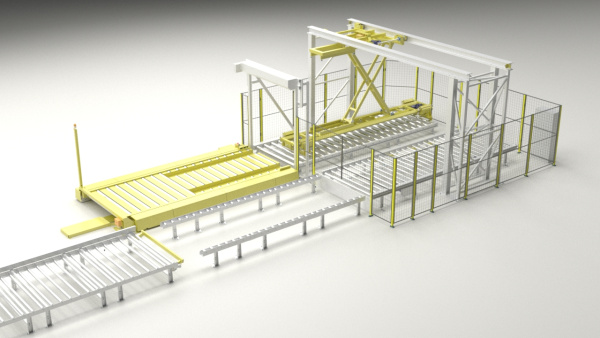

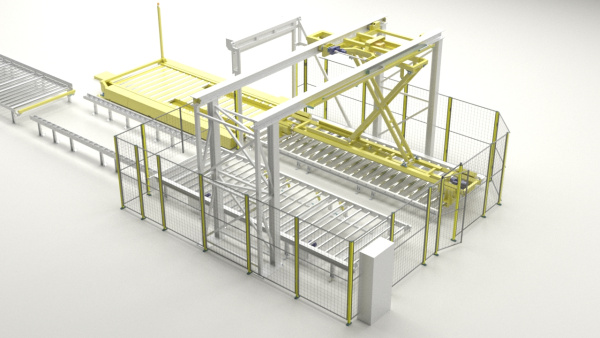

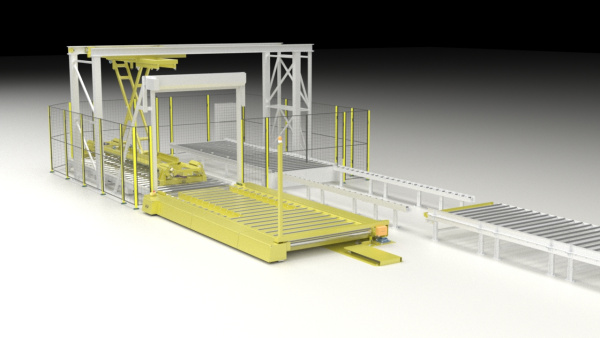

At the beginning of the new line are non-powered roller conveyors, where the material needed for the production of wooden pallets is stacked. The pallets are then compacted, moved to an automatic stacker, and at the end of the line, finished pallets of various lengths are delivered. They are also turned straight into the space so that the operator can conveniently remove them.

Previously, 2 people were needed, now 1 person presses the pedal and it's done in a few seconds

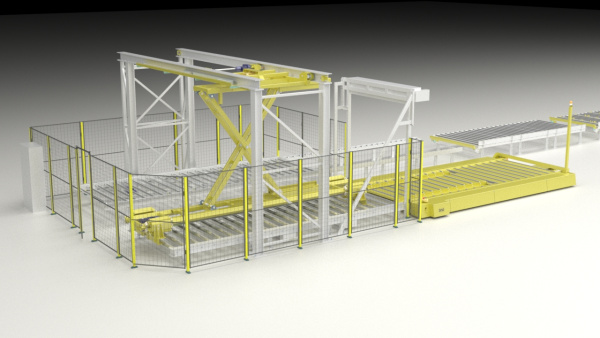

We have automated the movement and precise fixation of the inserted material on the production line. This has saved the company valuable time and the work is no longer physically strenuous for the workers. Previously, two people had to lay out the prisms on a table, align them manually at the end and set them apart with a meter to create precise gaps between the prisms. Only then could they place the battens on the prisms, thereby hammering the top of the pallet. Now there is no need to lift anything. The worker simply moves the material slightly into the free gaps on the conveyor and steps on the pedal. The wooden prisms are quickly aligned in all directions. Thanks to the nested alignment pins, they are also positioned at precise intervals.

The automated stacker stacks as many pallets as the production team determines

The compressed pallets are moved via a roller conveyor to an automatic stacker. There, the operator moves the pallet onto a powered roller conveyor and the manipulator takes care of everything itself. It stacks the pallets on top of each other in the required quantity and aligns them in all directions. The high-speed roller door is then raised and the pallets are moved onto a turntable – a transfer trolley with a roller conveyor. The operator gives the driving instruction via remote control and the trolley rolls the pallets into the space. This allows the operator to conveniently remove the pallets with a forklift.

Are you interested in our solution? Read how we designed a subsequent packaging line, or contact us directly. We will be happy to create a conveyor system tailored to your company.