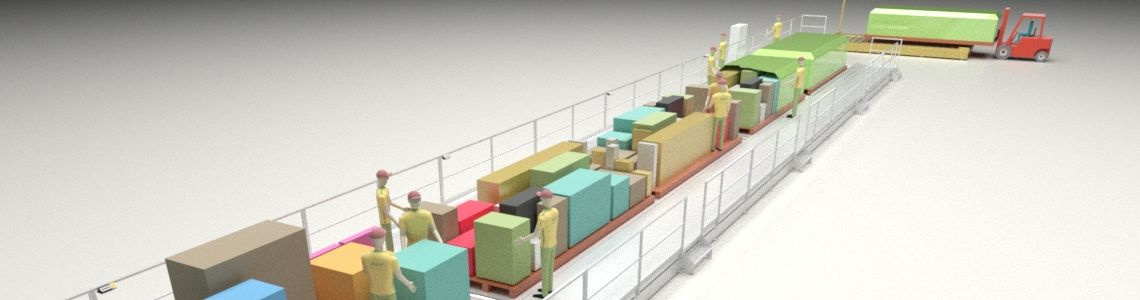

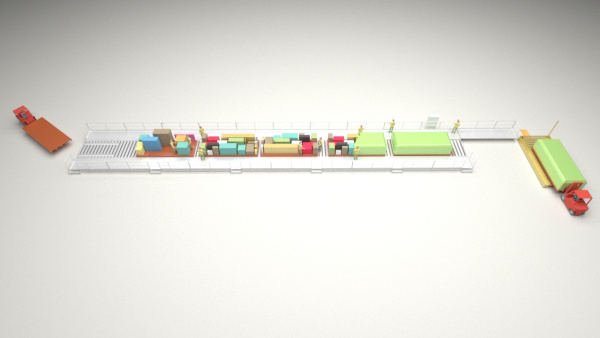

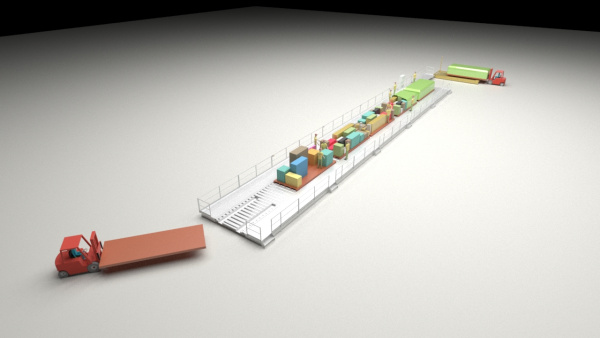

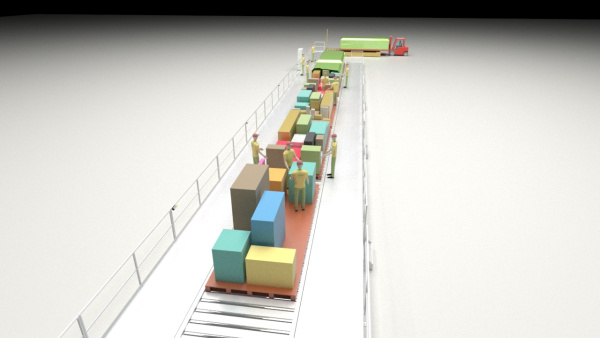

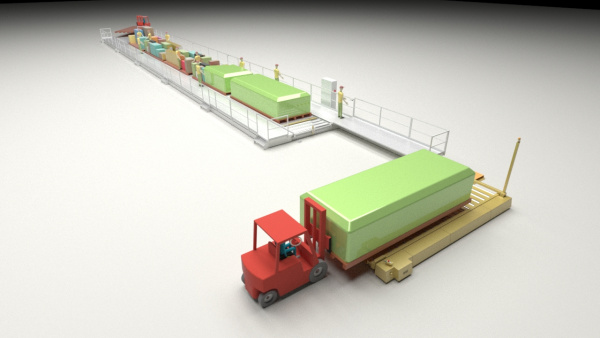

Long, wide and 10 tons. The new packaging line moves different types of pallets

written: 10.05.2021

Pallet packaging is complemented by SOLAS weighing

A company that deals with industrial packaging and logistics is our long-standing customer. Now, in addition to the pallet production line, we had to design a subsequent packaging line for them. Within a short time, we delivered a solution that enables accurate commercial weighing of pallets with an output for safe maritime transport according to the SOLAS specification. It works with different pallet sizes and automatically stops them above the scale integrated into the conveyor. It can also turn the load at the output by 90° to make the collection of packaged and weighed products as convenient as possible.

A 48-meter-long roller conveyor can easily carry 10-ton pallets

The new packaging line goes beyond the standard in terms of parameters. It has large rollers with a diameter of 133 mm and a length of 2450 mm. It consists of a 48-meter-long and 2.5-meter-wide driven roller conveyor, which is complemented by a walk-on service platform on the sides. The entire packaging line is divided into 6 parts. Each has a load capacity of 10,000 kg. At the beginning of the line there is an empty wooden pallet, at the end pallets with firmly attached packaged products are already leaving, which are additionally provided with a label with information about the total weight.

The new packaging line includes special wheels

The entire conveyor system consists of several parts:

- Roller conveyor, driven

- Roller conveyor, non-driven

- Roller conveyor, non-driven

- Commercial scale

- Turntable

- Transfer trolley with DAS block

DASblok refers to our own travel wheels. Since none of the competing solutions were suitable for us, we developed our own robust travel block. In this project, we used a DASblok with a rubber rim and placed it under a rotary transfer cart with a roller conveyor. This rotates the pallets by 90° so that the forklift operator can easily remove them at the exit.

The semi-automatic section stops and weighs the pallets itself

The section of the packaging line with the scale is semi-automatic. The program logic measures the pallet itself and stops it above the weighing frame, which is embedded in the roller conveyor. How does such weighing work? You press a button and the scale moves out from under the conveyor. The pneumatic bellows on which the scale is placed are inflated, the frame lifts the pallet with the products and weighs it. Then the bellows are released again and the weighing frame hides back below the level of the rollers. Finally, the device prints a self-adhesive label with the product weight and barcode.

Interested in more? Read how the entire solution was installed in Hungary.