Automatic transport of weldments for 14 metre trailers? Works even in a narrow hall

written: 28.11.2020Manual work in trailer production replaced by automatic transport of welded parts

A manufacturer of flatbed and platform trailers needed to switch from manual welding to robotic welding. They wanted to fully automate the transport of welded parts and design a variable conveyor system. One that would allow for the addition of further welding stations and be as safe as possible for workers. Our robotic welding solution made excellent use of the limited space and coped with the biggest challenge of the job – how to transport pre-tensioned weldments and weldments with protrusions in the contact surface.

Transfer carts and hydraulic scissor tables assist in the production of weldments weighing up to 2,500 kg

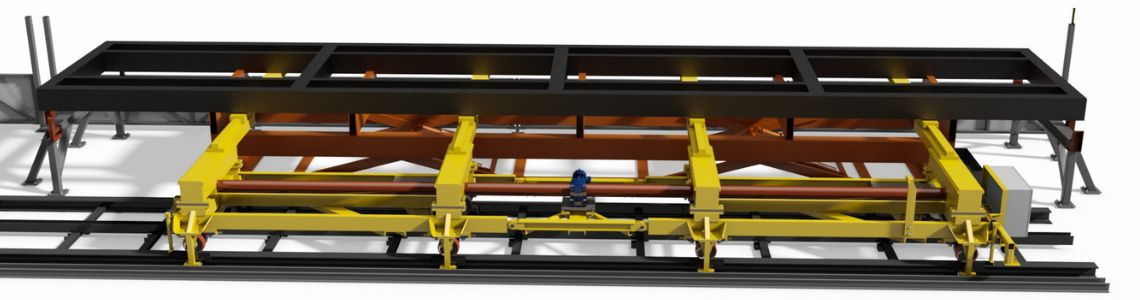

We designed a handling system with a solid structure, including transfer carts and hydraulic scissor tables. We retained the handling aisle and left enough space for line operators. Workers need sufficient space here, especially when loading and unloading.

We worked closely with Czech and international companies to create a customized conveyor solution. A welding positioner was supplied from Germany, and we prepared the welding facilities in cooperation with a Dutch company. We then used a Czech partner company for the electrical installation and programming. The result is a comprehensive system specializing in the automatic transport of weldments.

How does robotic welding work? Fast, precise, and safe

The new conveyor system with a travel distance of 85 meters transports metal frames for flatbed and platform trailers. Between the input and output workstations is a robotic welding station that works with weldments measuring up to 14 × 2.5 meters. The cycle time for their replacement is 30 minutes.

Operators use a bridge crane to place the assembled frames into the input workstations. The assembled frames are transported by a transfer trolley from the input workstations, which consist of two racks and a scissor tandem lifting table. It moves them to the positioners of the welding workstation. One weldment weighs up to 2.5 tons. Another transfer trolley transports the welded frames from the welding workstation positioners to the output workstation. Another advantage of the new solution is the backup transport option. There are bridge cranes above the transport system that can transport the frames under increased safety conditions in the event of a transfer trolley failure.

Safety during welding is ensured by gates and optical grids

The conveyor system consists of several separate safety sections. All these workplaces have safety fencing and secured entrance and sliding gates.

Do you want to streamline your welded product manufacturing? Write to us or give us a call. We will find the ideal solution for your operations.