Automated transport system takes wood production to a new level

written: 23.05.2025

Perfect teamwork from the crosscut saw to the planer

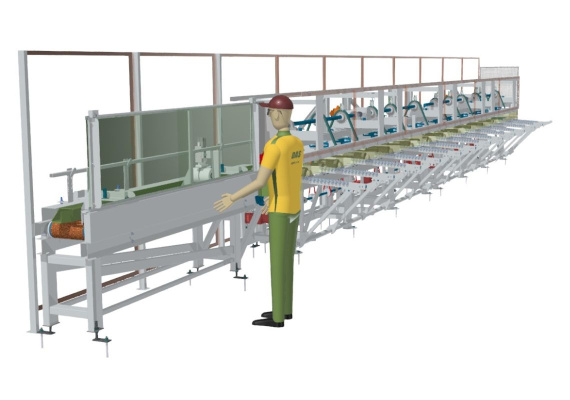

Wood processing requires precision and smooth material flow. We therefore designed the conveyor system as an interconnected whole, ensuring the smooth transfer of wood from the crosscut saw through the edger to the final planing stage. The individual parts thus function like a perfectly tuned orchestra.

The belt conveyor between the OptiCut 450 Quantum saw and the Ultra TT 1500 edger ensures fast transport of cut parts. Thanks to its adjustable height (640–1100 mm) and castors, it can be easily adapted to different operating conditions. With dimensions of 5.4 × 1.8 meters, it offers high flexibility in material handling. A 1.5 kW converter enables smooth speed control, and a stop plate reliably prevents the slats from falling after being ejected transversely from the sorting belt. At the end of the conveyor, there is a triangular storage area for safe storage of material.

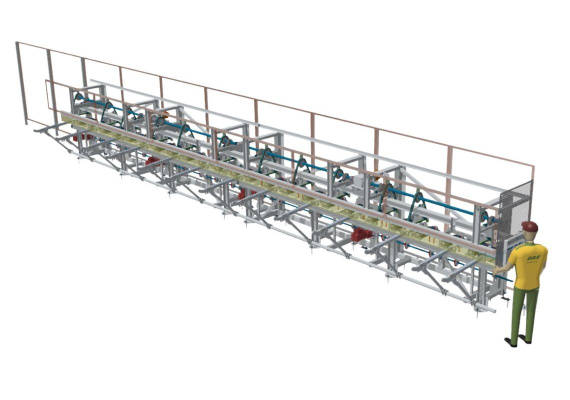

The biggest star of the system? Accumulation chain conveyor for precise and fast positioning of parts

The robust accumulation conveyor can handle slats of various lengths – from short sections to 12-meter pieces. It gently transfers freshly cut slats to the accumulation conveyor using powered chains. Thanks to lifting electro-pneumatic cylinders, plastic carriers, and smart logistics with a Siemens S7-1511F control system with a KTP700 touch panel, the slats are not only protected from damage, but also do not touch each other during transport. All this with a capacity of up to 60 curing stations.

Precise ejection even under high loads

The belt accelerator conveyor with servo drive easily adjusts the production speed, and its two chain ejectors quickly and accurately distribute the slats in the appropriate directions. The pressure wheel with a pneumatic cylinder and adjustable guide ensure precise guidance of the slats even with different widths of input material. The new solution is therefore ideal for operations where individual formats change frequently.

At the system outlet, there is a roller conveyor that knows exactly where each piece of material should go. It smoothly moves the planed slats and, thanks to the possibility of regulating the feed speed, the output can be easily adapted to the current operational needs. The rollers are driven by asynchronous motors with a gearbox, which ensure uniform movement.

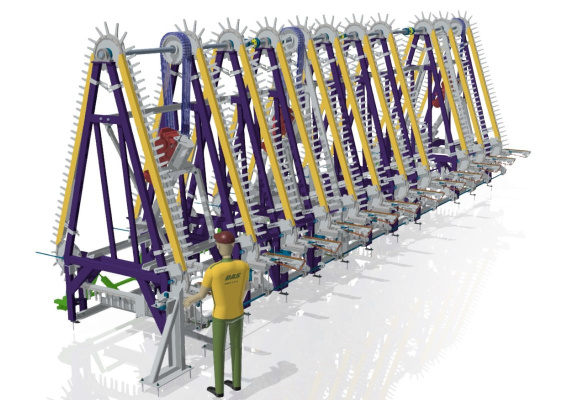

The result? Greater efficiency, fewer rejects, and safer operation

The central electrical installation with a switchboard, servo drives, sensors, and safety features ensures not only reliable operation but also connection to all other machines in the production line. All devices communicate via the Profisafe system and meet the highest safety standards. Galvanized rollers, fencing at all critical points, and access doors with safety features are also standard.

The entire conveyor is designed with an emphasis on flexibility, precision, and easy adaptation to the production pace – so that it always supports the smooth operation of the entire line.

Are you interested in our solution? Take a look at other examples of our work

Every operation is different, and our conveyor systems respect that. We design everything individually according to the specifics of the operation – from the layout of the hall to the nature and rhythm of production. Take a look at other solutions from our workshop:

- Inter-floor transport of metal pallets moves empty and full pieces fully automatically. It can handle pallets up to 2,950 mm high and with a load capacity of up to 2,500 kg.

- A platform truck the size of a small apartment is already helping the largest Czech manufacturer of concrete reinforcement. The 5 × 11 meter platform could easily carry 20 cars.

- The automated pickling line, which we supplied to a manufacturer of heating technology, also performs pressure tests. The entire system is powerful, reliable, and perfectly secure.